How Do Butterfly Valves Work?

How to Fix a Leaking Butterfly Valve?

September 12, 2019

Where are Butterfly Valves Used?

September 12, 2019A high performance butterfly valve is a quarter-turn valve best suited for handling large amounts of liquids or gases. Butterfly valves are easy to handle and are used in many flow control and throttling applications.

In this article, we are going to show you how butterfly valves generally work.

Some Basic Information About Butterfly Valves

Among the other types of valves, the butterfly valve is the most economical and the cheapest shut-off valve.

Working Principle

A butterfly valve consists of metal disc that rotates about the stem and initiates a tight shut-off on the circumference of its resilient seat. The stem may be mounted in the middle or attached offset. There is also a packing component which provides an extra seal for protection in the event that the rubber seat is damaged by fire.

Since it’s a quarter-turn valve, you only need to turn the handle to 90 degrees to fully open the valve.

VIDEO:

How Do Butterfly Valves Operate?

The disc component can be operated through multiple ways. It can be through a packing from a pneumatic actuator, an electric motor, a solenoid or a hydraulic piston and cylinder.

How to Make Butterfly Valves Work with a Handwheel

To make it work, simply turn the handwheel to its open or close position. This is the simplest (and oldest) way to operate a butterfly valve. Hence, they are not automatic. Manually-operated valves can be equipped with a lever, wheel or a gear connected to the stem. These valves are typically used in systems that do not require automatic operation.

In large plants such as in refineries and power generation facilities, high-performance butterfly valves can be seen with a gearbox actuator and a handwheel connection through its stem.

These are power-operated valve actuators which initiates automatic opening and closing of the valve. Some of these valves have switches so you can remotely monitor the position of the disc. Thus, the purpose of the handwheel in this type of system is for emergency reasons when power is not available.

How Pneumatic Actuators Make Butterfly Valves Work

Pneumatic actuators are powered by air or gas. It can be automatically or semi-automatically operated. The design is quite simple and it is easy to operate.

- A certain pressure range is set in the system.

- When the system detects that its about to exceed the air pressure, a diaphragm modulates the opening and closing amount of the butterfly valve.

- Pneumatic Valves can be used for throttling or as throttle butterfly valves.

This type of operation doesn’t use a limit switch like the electric-operated butterfly valves, but instead, uses the following for operation:

- Spring-Return – Air pressure induces the movement of the spring to move the stem.

- Double Acting – Air is applied in two inlets to initiate movement of the valve from close to open position.

How Hydraulic Actuators Make Butterfly Valves Work?

Basically, hydraulic actuators work by sensing the fluid pressure to initiate valve movement. These types of valves are used for applications that receive huge amounts of force.

- Fluid pressure acts on a piston cylinder to convert it into linear motion.

- This piston is connected to an actuator that converts linear motion to rotary movement.

- Its torque initiates the movement of the butterfly valve stem, opening when the pressure is higher than the set value and closing when the downstream pipe needs to be bled.

How Electric-Operated Butterfly Valves Work

These types of valves use an electric actuator for operating the valve in an open and close position.

Electric-operated butterfly valves needs electricity to operate. It is one of the most reliable solutions for large plants and applications.

Considering Body Material

Also note that butterfly valves come in many body, disc and seat materials that are meant for different applications. Aluminum valves are used for lightweight applications; stainless steel butterfly valves are for corrosive medium transport; carbon steel (WCB high performance butterfly valve) are for high strength and high-temperature applications; and austenitic steel valves are for cryogenic applications.

Considering Seat Material

Seat material may either be metal seated or resilient seated. The difference between them can be easily seen in their structure. Metal seated valves have metal-to-metal contact points and have no elastomer or teflon seating unlike resilient seated valves.

The withstanding temperature and pressure and sealing performance are also different for each valve. While metal seated valves are hard and can withstand high temperatures without wearing out, they are not as good as resilient seated valves in terms of sealing. Resilient seated valves, on the other hand, may not withstand high temperatures.

Considering Offset Designs

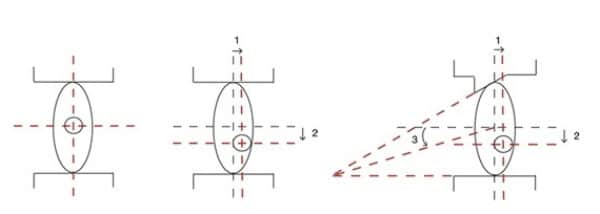

Offset designs also vary for butterfly valves. There are 3 types of offset design: zero offset, double offset and triple offset. Typically, soft seated valves are concentric/lined type/zero offset, while metal seated valves are for eccentric designs (double or triple offset).

How Do Zero Offset Butterfly Valves work?

Concentric or zero offset butterfly valves have their stem line at the center of the valve body, where the disc is centrically positioned.

Since this has the simplest design for a butterfly valve, it is obviously used in general service types. This can be in applications that do not require high pressure and high temperature. In fact, zero offset butterfly valves can only be used in systems with 250 psi maximum pressure and 400 degrees fahrenheit. Thus, they are used for the lowest class standard which is Class 150 rating.

How it works is simple.

- The stem, attached to the center of the disc, is connected to an actuator. The actuator can be powered by an electric source, pneumatic diaphragm, hydraulic piston or by manually turning a handwheel.

- When a set pressure is met by the system, the disc, forced to move by the actuator, turns parallel or perpendicular to the flow of the medium. Parallel to let the fluid pass; perpendicular to stop the fluid.

- For throttling services, the valve can be turned open slowly to let the media pass through with smaller amounts.

How Do Double Offset Butterfly Valves work?

For high temperature and high pressure applications, we cannot use a zero-offset butterfly valve. Metal seated valves are suitable for this type of application as it has higher mechanical properties than soft seated valves.

Double Eccentric Butterfly Valves are suitable for heavy duty applications such as high temperature and pressure applications as its dual offset design is meant for anti-wear of metal-to-metal seats. The dual offset design also prevents friction or rubbing between the metal surfaces upon closing the valve.

Since this type of valve is simpler in design than the triple offset valve, it follows that it is cheaper. It is a high performance butterfly valve with two offsets of the stem. The movement follows a specific cone profile to address shut-off of metal seats.

Here’s a detailed VIDEO to help you understand how double offset butterfly valves work:

How do Triple Offset Butterfly Valves work?

For triple offset butterfly valves, manufacture and assembly is quite difficult as compared with the double offset and concentric butterfly type. Hence, it is the most expensive. But its expensive price comes with greater benefits, especially for systems requiring high-performance valves.

Triple offset valves are typically used for tight shut-off in piping systems for petroleum and gas applications.

There are three offsets for triple offset butterfly valves all mounted eccentrically. This helps provide a tighter seal. In this type of valve, there is a combination of the double offset design and an additional offset of the disc seat axis.

With the triple offset design, sliding between the seat and disc can be eliminated. It is recommended for high pressure and high temperature applications such as for Class 150 to 600 rating.

Here’s a detailed VIDEO to help you understand how triple offset butterfly valves work:

Conclusion

Butterfly valves work very simply. You don’t need a diverse technical knowledge to figure out how it works. What really matters is how reliable they are made to perform accurate and safe fluid regulation, control and throttle. If you want to explore our range of high quality, high-performance butterfly valves, you may go to our website and reach out to us.

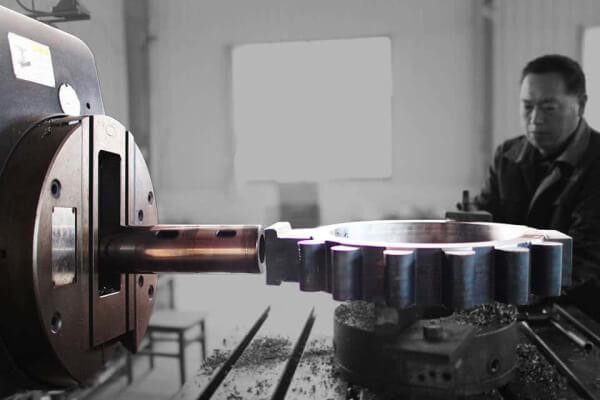

Huamei is a China high performance butterfly valve manufacturer. We have a wide range of butterfly valve portfolio ranging from different seat design, body, disc and stem material and end-type connections. We also do OEM/ODM services. Feel free to contact us for more information and for quotation requests.