Butterfly Valves by Materials

Huamei Machinery is a professional manufacturer of double offset high performance butterfly valves, our valves are available in LUG, WAFER or DOUBLE FLANGE connections. End flange specifications are available in ASME Class 150/300/600, DIN ISO PN10/16/25/40/100.

WCB (UNS Code J03002) is covered by ASTM A216 standard, which specification covers carbon steel castings for valves, fittings, flanges and other pressure-containing parts for high-temperature service and the quality required for assembly with other castings or wrought steel parts by fusion welding. These grades are all "cast" grades meaning they are made through "casting" which is a manufacturing process where a liquid material is poured into a mold and allowed to harden.

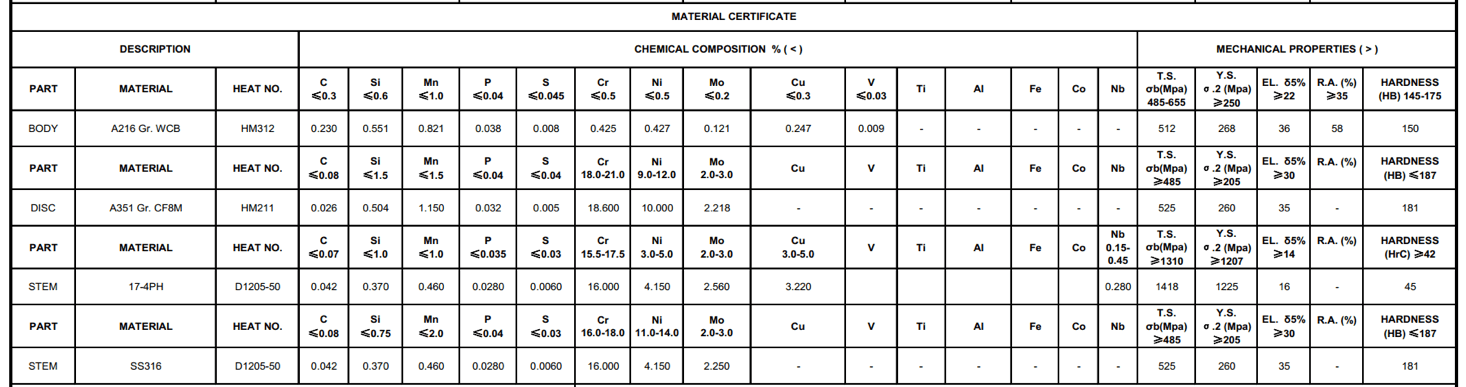

HUAMEI MACHINERY offers double offset high performance butterfly valves with two grades of carbon steel (Grades WCB and LCB for customers to choose from for different service conditions. Standard mill certificate be offered for each order as below template.

CF8M is a cast austenitic material for pressure containing parts, which covered by ASTM A351 and ASTM A743 standard. The corrosion resistant alloy Type 316 is molybdenum steel possessing improved resistance to pitting for solutions containing chlorides and other halides. In addition, it provides excellent elevated temperature, tensile, creeps, stress and rupture strengths.

As with CF8M, the first character (C) means the alloy is intended for "Corrosion Resistant" service. The second character (F) is the approximate location on the iron-chromium-nickel (FeCrNi) ternary diagram and indicates the iron, chromium and nickel content. The third character (8) represents the maximum carbon content in increments of 0.01%. In this instance, 0.08%. Finally, the character (M) states that Molybdenum is present.

HUAMEI MACHINERY offers double offset high-performance butterfly valves covering ASTM A351 CF8M material. Standard mill certificate be offered for each order as below template.

Duplex stainless steels are the most recent family of stainless steels. They are called duplex (or austenitic-ferritic) grades because their metallurgical structure consists of two phases, austenite (face-centered cubic lattice) and ferrite (body-centered cubic lattice) in roughly equal proportions. They are used for their good mechanical properties in the as-cast (and therefore as-welded condition) and/or their excellent corrosion resistance properties (particularly to stress corrosion cracking).

HUAMEI MACHINERY offers double offset high performance butterfly valves covering Duplex Stainless Steel (2205 & 2507) material. Standard mill certificate be offered for each order.

Hastelloy C276 is a nickel-molybdenum-chromium superalloy with an addition of tungsten designed to have excellent corrosion resistance in a wide range of severe environments. The high nickel and molybdenum contents make the nickel steel alloy especially resistant to pitting and crevice corrosion in reducing environments while chromium conveys resistance to oxidizing media. The low carbon content minimizes carbide precipitation during welding to maintain corrosion resistance in as-welded structures. This nickel alloy is resistant to the formation of grain boundary precipitates in the weld heat-affected zone, thus making it suitable for most chemical process application in an as welded condition.

Although there are several variations of the Hastelloy nickel alloy, Hastelloy C-276 is by far the most widely used. HUAMEI MACHINERY offers double offset high-performance butterfly valves covering Hastelloy C-276 material. Standard mill certificate be offered for each order.

Aluminium bronze is a type of bronze in which aluminum is the main alloying metal added to copper, in contrast to standard bronze (copper and tin) or brass (copper and zinc). A variety of aluminum bronzes of differing compositions have found industrial use, with most ranging from 5% to 11% aluminum by weight, the remaining mass being copper; other alloying agents such as iron, nickel, manganese, and silicon are also sometimes added to aluminum bronzes.

Aluminum bronzes are most valued for their higher strength and corrosion resistance as compared to other bronze alloys. These alloys are tarnish-resistant and show low rates of corrosion in atmospheric conditions, low oxidation rates at high temperatures, and low reactivity with sulfurous compounds and other exhaust products of combustion. They are also resistant to corrosion in seawater.

HUAMEI MACHINERY offers double offset high-performance butterfly valves covering Aluminum Bronze material, which is widely used in sea water-related service, water supply, oil and petrochemical industries.

Titanium alloys are metals that contain a mixture of titanium and other chemical elements. Such alloys have very high tensile strength and toughness (even at extreme temperatures). They are light in weight, have extraordinary corrosion resistance and the ability to withstand extreme temperatures. However, the high cost of both raw materials and processing limit their use to military applications, aircraft, spacecraft, bicycles, medical devices, jewelry, highly stressed components such as connecting rods on expensive sports cars and some premium sports equipment and consumer electronics.

HUAMEI MACHINERY offers double offset high performance butterfly valves covering Titanium material for wide applications.

Request A Free Quote

Contact info.

Huamei Machinery Limited

Address: Economic and Technological Development Zone of Ningjin County, Dezhou City, Shandong, China 253400

Tel: +86 (0) 532-84688512

Fax: +86 (0) 532-84688513

Email: sales@huameimachinery.com