Butterfly Valves: The Ultimate Guide

If you are looking for an easy installation and low-cost valve for fluid flow control and throttle with a tight shut-off, then look no further. You’re probably looking for a butterfly valve.

We don’t exactly know what and where you will be using it for, but in this guide, you will find plenty of things insightful about Butterfly Valves. First, you will learn the basics on butterfly valves, its operation, installation and maintenance. Then, we will show you how a designer, engineer and investor thinks and does before actually buying high-performance butterfly valves.

Beware that this IS an actionable guide. You might want to take down notes which can help you decide on how to choose and purchase butterfly valves.

Contents of this Guide:

What is a Butterfly Valve?

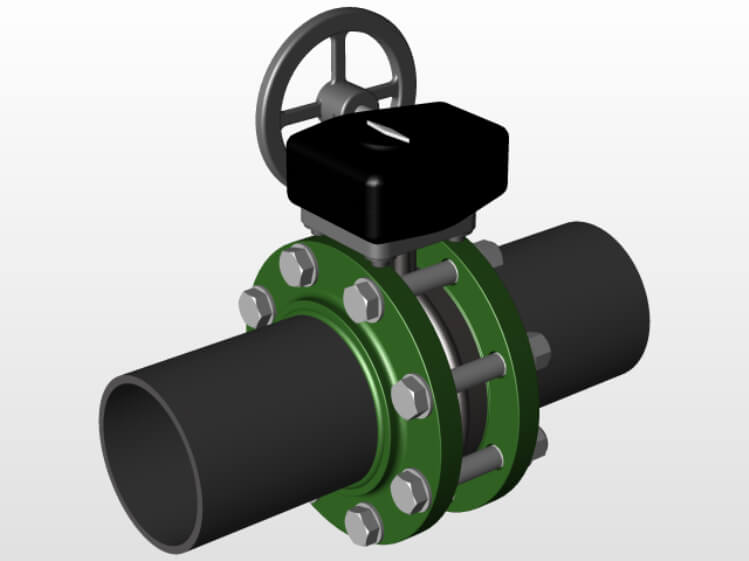

A butterfly valve is a quarter-turn valve that initiates throttling and flow control of fluids. Given its name, you can easily visualize a thin metal disc that “flutters” about a fixed axis (stem assembly). The opening and closing mechanism allows and restricts the flow of a medium between an upstream and downstream pipe.

What type of valve is a butterfly valve?

In a more technical tone, a butterfly valve is a regulated rotary valve that consists of a rotating disk which directs the flow of fluid in a system. Basically, the disk is operable up to 90 degrees and that’s why it is called a quarter-turn valve. A butterfly valve controls the flow linearly and can be bi-directional. The configuration and operation of the valve is similar to a ball valve, but it is lighter and less costly.

For throttling services, you can use a high performance butterfly valve, which is a higher industry standard for larger applications. Generally, this type of valve is manufactured to process large capacities and oftentimes, viscous and seawater medium. We will get more into high performance butterfly valves later.

You can find butterfly valves typically in piping systems delivering large volumes of fluids. These valves are delicate and not recommended to handle dry bulk solids as they can choke or break the butterfly valve.

The operation can be through a packing from a pneumatic actuator, an electric motor, a solenoid or a hydraulic piston and cylinder. Either way, this type of valve is the most economical and the easiest to handle. Butterfly Valves are also more affordable than other types of valves.

Advantages

Here are some of the advantages of butterfly valves compared with other valve types.

- Lightweight and compact

- Easy to install

- Low-pressure loss

- Low maintenance

- Simple, rapid operation

Disadvantages

- The disc can interrupt flow even when it is open

- Not recommended for high differential pressures

What are Butterfly Valves used for?

Butterfly valves are used in many industrial applications such as:

- HVAC

- Vacuum service

- High-temperature applications

- Refrigeration and Air Conditioning systems

- Irrigation and agricultural needs

- Corrosive processing

- Lubrication

- Petroleum Industries

- Wastewater treatment

- Slurries

- Sanitary valve applications

- Sprinkler and fire protection systems

When it comes to choosing a butterfly valve type for a specific application, one can look into a pile of different valve classifications. Seat, body and disc materials are varied depending on the service they will be used.

Regulating Fluid Flow

In butterfly valves, fluid flow constriction and control is easily done by just turning the valve handle. As it is a regulating valve, it controls the flow rate of system through the help of actuators. Basically, when a flow monitor senses that a set parameter (differential pressure) has been reached, it will signal the valve actuator to close or open the valve.

To control a regulating valve remotely, it must have a flow controller which automatically communicates with the valve mechanism based on the flow rate.

Flow Isolation

Butterfly valves are used typically in low pressure and low-temperature applications. They are lightweight and easy to manipulate and its quarter-turn action can also be used for flow isolation.

Backflow Prevention

In food industries where there are aggressive washdown processes, butterfly valves can be used for backflow prevention. This is necessary, from standard regulations, as it is aimed in food processing to deliver procedures in sanitary conditions.

General Butterfly Valves for Smaller Processing Units

For example, lightweight and AWWA butterfly valves are meant for water lines and potable water control applications. Other light duty valves can be used for aquariums and sprinkler systems. Some valves are also meant for fuel flow control.

High-Performance Valves for Heavy-duty industry applications

For large and heavy-duty applications such as in oil and gas industries or high-pressure controls, high-quality and high performance butterfly valves are needed. These high-grade valves are certified and quality tested to meet quality demands and international standards.

Constant Load Applications

It should be noted that even though butterfly valves can handle large volumes of liquids, care is needed when controlling its load. This type of valve has a limited capacity in handling small load changes as only allowing a few millimeters opening is equivalent to a large volume difference. However, designs can be enhanced to diversify its control range, especially in larger applications where pressure is intricately regulated.

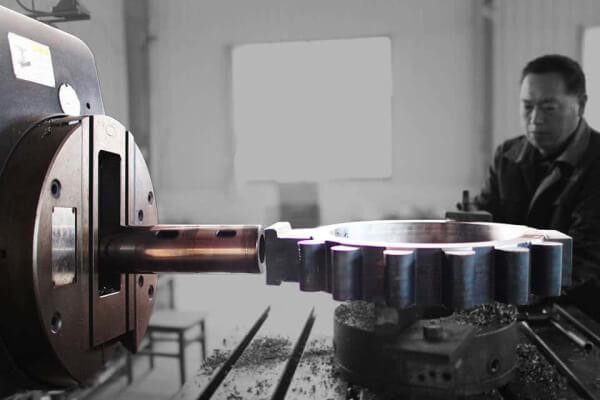

Parts of a Butterfly Valve

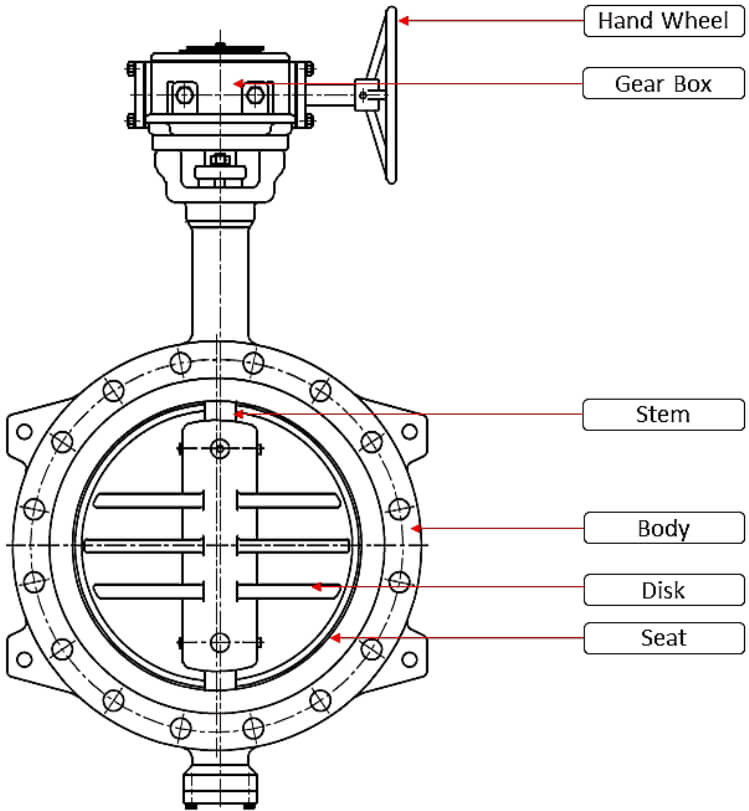

Generally, there are four main parts: the stem, disc, seat and valve body.

Valve Body

The valve body fits between the pipe flanges. It holds the other valve component into place. The valve body can be lug-type or wafer type.

It can also be made of different materials depending on the application. For example, Carbon steel is a general type of valve body used in common applications that do not require corrosion resistant properties. Stainless Steel, Nickel Alloy and Titanium Alloy, on the other hand, can be used for corrosive environments.

Disc

Attached to the valve body is the disc that functions as a gate that stops fluid flow. Again, it can be made from different materials depending on application.

Seat

Lining the internal valve body is a strong elastomer or metal anti-leak seal that secures the disc in place. It main function is This can be soft seated or metal seated. Soft seats (PFTE/RTFE) can be made of O-rings or rubber rings, while metal seals can be inconel or stainless steel.

Stem

The stem is valve component that usually lies protected inside the disc in resilient valves. However, in high-performance valves, it is typically in contact with the fluid.

The stem connects the disc to the actuator, like a shaft connecting a propeller to a motor. Similarly, the rotary action of the stem initiated from the power of the actuator is transmitted to the disc, allowing the close and open position of the valve.

Types of Butterfly Valves

How many types are there?

Butterfly valves can be categorized in many types. The most known classification is by end-connection type (lug or wafer). But it can also be classified according to seat design, body material and offset design. Some even classify these valves according to their mode of operation.

But each classification can also be intertwining. For example, you need a specific design for severe, heavy-duty applications where vibration is high and the substance is corrosive. In this type of scenario you can use a lug-style (end-connection type), titanium alloy (body material type) butterfly valve – two different valve classification in a row.

What are the two body styles of butterfly valves? Classification by end-connection

- Wafer Type Ends – have a flexible seal that protects the system from backflows which occurs when bi-directional pressure occurs

- Lug Type Ends – has threaded “lugs” or inserts around its circumference that permit for bolt passages.

Seat Material

- Soft Seated (PTFE/RTFE) – a synthetic fluoropolymer that is highly resistant to chemicals as compared with other plastics. Plus, PTFE lined seat has a low coefficient of friction which makes it ideal for low torque applications.

- Metal-to-metal (SS316 and Inconel) – Inconel butterfly valves are used for applications requiring heavy duty seats such as in handling bulkier fluids. On the other hand, Stainless steel butterfly valves can be used in processing corrosive substances as they have a higher resistance to corrosion than inconel.

Offset Design

- Zero Offset Butterfly Valves – Concentric disk valves have their seals line against the edge of the elastomer lining which ensures tight shut-off. The stem is mounted in a vertical axis at the center of the disk.

- Double Offset Butterfly Valve – The Double Offset or Double Eccentric Valve is a high performance butterfly valve which is designed with two offsets of the stem. The movement is calculated with a specific cone profile to address shut off of high pressure applications.

- Triple Offset Butterfly Valve – There are three offsets for triple offset butterfly valves all mounted eccentrically. This helps provide a tighter seal. In this type of valve, there is a combination of the double offset design and an additional offset of the disk seat axis.

Body Material

- Carbon Steel – This type of butterfly valve is relatively cheaper than other types of butterfly valve material, but it cannot be used for corrosive applications.

- Stainless Steel – specialize in corrosive piping applications. As the stainless steel material is a combination of iron, nickel, chrome (10.5%) and sometimes Molybdenum, it possesses both strong acid endurance and strength of steel.

- Titanium Alloy – This type of valve has the highest strength-to-weight ratio as compared with other metal valves. It is lightweight and corrosion-resistant.

- Nickel Alloy (Hastelloy) – one of the strongest and most versatile types of valve. They are used in specific applications that require extreme resistance to fluid impact and high and low temperatures

- Aluminum Bronze – corrosion resistant valves for seawater piping systems. A distinct feature of this valve is in prevents biofilm formation. Nickel aluminum bronze is a composition of 10% aluminum, 5% iron and 5% nickel.

For a more detailed discussion of butterfly valve types, you can refer here.

Valve Actuation

There are many ways to operate a butterfly valve. It can be manual, semi-manual or automatic.

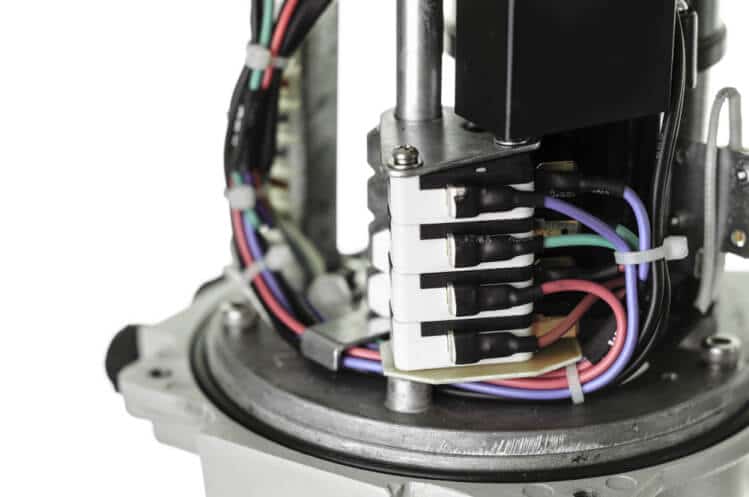

Electric-Operated Valve – use an electric actuator for operating the valve in an open and close position.

Pneumatically-operated valves – Pneumatic actuators are used to operate these types of valves for shut-off pipelines. Pneumatic Butterfly valves are typically used for transferring compressed and pressurized air.

Hydraulic Piston – These types of valves are used for applications requiring huge impacts or force for opening and closing the valve.

Manual or handwheel operation – These types of valves are manually operated through a hand-wheel or crank. Hence, they are not automatic.

How Do Butterfly Valves work?

Check out this video to see how this type of valve work.

Installation

Here are few installation tips, as well as a checklist to take note of:

- In order to check parts of the butterfly valve, you can be able to disassemble it in order to further inspect its parts. For guidance, you can check out thison assembly and disassembly of butterfly valves.

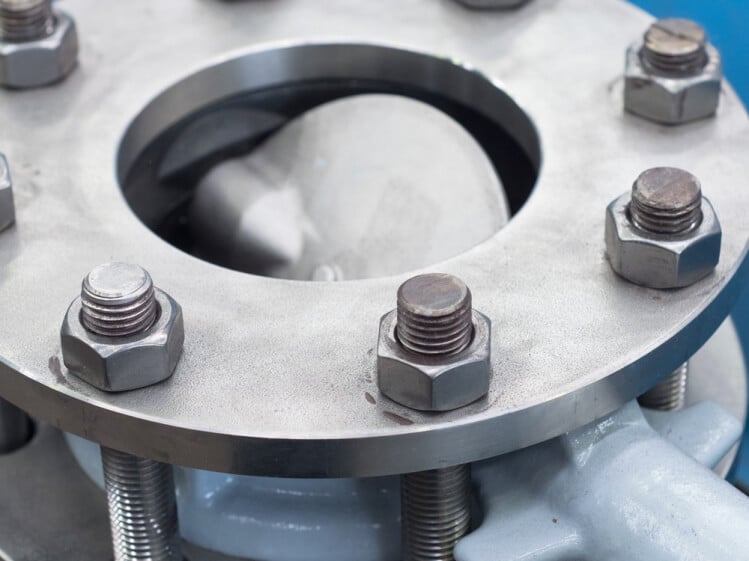

- Before anything, see to it that the flange and pipeline are clean from foreign materials. These can damage the seat or disc and can also cause disc to movement restrictions.

- Since resilient seated valves extend to both faces, gaskets are not needed.

- In order to easily insert the valve body, spread the flanges and align the pipe-work. With this the valve body is inserted even with no contact to pipe flanges.

- Partially open the valve disc to prevent the valve from jamming.

- Insert the valve between the flanges, taking care not to damage the seat faces.

- When you lift the valve, hold it by the locating holes. Also, you can tie up a nylon sling around the body or the neck.Make sure you do not lift the valve at the actuator or its operator.

- Once the valve is placed and aligned in between the flanges, insert all the bolts before hand-tightening them.

- Slowly open the disc. This will test if it has the right clearance form the inside of the pipes.

- Afterwhich, a gradual closure of the valve should also be done to verify enough clearance from the disc to the pipe flanges.

- Fully open the valve, and start to tighten all of the bolts.

- To test proper clearances after fastening the valve in the pipeline, repeatedly fully open and close the valve. This ensures the valve functions well during operation.

Maintenance of Butterfly Valves

Valves, as having constant contact with fluids, are prone to rusting and corrosion. The applied grease on the butterfly valves should also be monitored.

- Apply grease at constant intervals, based on manufacturer’s recommendations. To apply grease, the grease fitting is located at the top of the valve. Also, to ensure that the right amount of grease is placed, apply grease to the neck of the valve until old grease flows out and is replaced by newly applied grease.

- For greasing the gearbox, a lithium-based grease is recommended.

- If cleaning is necessary, you can use silicon-based lubricants and other silicon-based products.

- When not used regularly, exercising the valve by rotating it once a month can ensure the valve will continually be operational.

What to Consider When Choosing Butterfly Valves?

When choosing butterfly valves for your operation, you would need to determine a few things before jumping in with the technical specifications of the valve. These basic information are the valve application, type of fluid, mode of operation and mode of installation, which are expounded below.

Valve Specific Application

The first thing you have to determine when choosing a butterfly valve type is to know what you will use it for. Do you need it for flow control applications such as regulating or stopping fluid flow?

Type of Fluid

Next is to know what type of fluid or substance will be circulating your system. Butterfly valves can generally accommodate liquids and gases, but not bulk solids. Also find out the properties of your media. It could be corrosive which requires stainless steel valve body and disc. However, for general fluids such as water, you can use carbon steel or cheaper alloys.

Mode of Operation

After knowing the type of fluid, you can choose the mode of operation of the butterfly valve. Manufacturers and suppliers usually have a range of choices for this. They would have manually operated, semi-automatic or automatically-operated valves. This would depend on the location of your valve, application, cost and on how often you need to turn on and off the valve.

Mode of Installation

Lastly, you should be able to see to it if you would need to flange the valve at both ends, weld it or screw it in between the pipes.

Upon determining these necessary information, you can now determine the technical specifications regarding your butterfly valve installation as coordinated with the manufacturer or supplier.

Capacity

The capacity includes the flow rate or the rate at which the material will pass through. This parameter also accounts for the safe internal pressure capacity of the valve. Make sure to check the butterfly valve specifications to ensure that you buy a valve sufficient to what your system needs.

Level of Precision

Each valve from a supplier specifies valve specifications which states the leakage volume or amount, if there is. It also indicates the shut-off position specs, the width of the passage and the volume of fluid that it can accommodate when fully opened.

Operating Life

Typically, you can find the operating life of the valve in the specifications sheet. Overall, butterfly valves promise less maintenance activities and can still give bubble-tight shut-off.

Pressure Drop

Pressure drop is an important parameter when sizing the valve for your specific application. It describes the difference in pressure which occurs between the outlet and inlet of the butterfly valve.

It is recommended that “If the pressure drop across the fully opened valve is not a large enough percentage of the total system drop, there will be little change in the fluid flow until the valve closes. In this case, a fast acting valve would be appropriate.”

| Consider that 25% to 50% of the total system pressure drop of the butterfly valve should be absorbed by the valve. |

How to Choose the Best Butterfly Valve Manufacturer

If you are planning to search for the most reliable butterfly valve manufacturer, there are a few things you should look for to know that you have chosen the right one. There are a pool of valve manufacturers to select from but how do you know you have fished out the right one?

Let us guide you with the following questions to help you choose the best butterfly valve manufacturer:

How to inspect butterfly valves?

First is inspection. You can’t buy a product you haven’t even inspected. Here are some of the things you should check in the butterfly valve:

- Check the valve body if it has scratches or deformations or cracks. If there is, this can result in the wrong positioning of the valve during installation so be wary of this. Also check if the seal is new. If there are visible cracks, it means it’s old.

- See if the disc is secured and there’s no deformations. Also examine if it can perfectly seal on the seat.

- Examine the seat if it is new.

- See that the stem is straight and not deformed.

- Examine the condition of the o-ring and packing gland.

Do they have the proper certification?

A butterfly valve supplier should have an ISO certification. Some valve manufacturers place this on their websites. Having this certification ensures that the facility meets the valve standards and quality in their manufacturing process and end products. It also notes that the manufacturer takes full responsibility for their product quality. You need to see their ISO certification first before you make any purchase for your own safety.

What is the cost?

Cost is actually one of the first things clients look for. For this, you can either see butterfly valve prices online or you can contact specific valve suppliers. If it’s a physical conversation, chances are, you can readily negotiate. However, you might want to see first the cost of China butterfly valve manufacturers as they offer huge savings on valve price. Again, to make sure that you are getting a high quality valve, you should look for proper company certifications.

Is there an After Sales Service?

The best manufacturers provide after sales service. This is one of the most crucial aspects in choosing a valve provider. When you see a lot of good testimonials about the company, it must mean they provide good quality service and perhaps they are true to their word. Also, valve suppliers who have professional staff ready and willing to solve your product problems are the best companies. So you should carefully choose who among the valve suppliers actually care.

How about repair services?

It is not uncommon that a few problems may arise upon installation of the butterfly valve. Although this can barely happen if you install it right, there may be times that it is not your fault why it does not work well. Manufacturers who provide clients with the best repairing services are top-notch.

These services may range from repairing to replacing your valve part and accessories.

Since Huamei is a butterfly valve manufacturer, we provide professional repair service along with our after sales service. Repair service may include repair, replacement, overhaul or instrumentation if necessary.

Do they have Warranties?

Warranties are protectional tools which ensures that you are protected from defective products over the span of the warranty period. Be sure to look for a valve manufacturer that promise product warranty.

Huamei offers 18 months warranty, complete with customer support, repair services and aftersales service to ensure that you get the best experience with your purchased high performance butterfly valves.

Do they have a good company reputation?

It also matters that the supplier/manufacturer has a good reputation which reflects the quality of the product they deliver, the services they provide, and the response time on queries. You can verify this by simply checking their testimonials, history and ratings from other customers.

Frequently Asked Questions

Have some confusion? Here, we have gathered some of the most famous FAQ about butterfly valves that may answer your question in mind. However, if you did not find the solution here, just contact us for more information.

1. Are butterfly valves good for throttling?

They are mainly used for regulating large fluid flows, including viscous slurries, but it should be noted that they are not meant for precision throttling.

2. Do butterfly valves require gaskets?

Butterfly valves are available with built-in elastomer seal that rests on flanges to prevent leaks. So most of them do not require additional gaskets.

3. Can Bi-directional high-performance butterfly valve supply for dead-end services?

Bidirectional high-performance butterfly valves can be used for dead-end service. But it should be noted that for such service, you cannot subject it in high-pressure applications.

A valve used for a normal service with 1000KPA can be used on a dead-end service but with only 500KPA. The high pressure may tend to cause the seat retainer to unload. The seat retainer may be bolted to prevent this, but the easiest way is to install it with a bolted flange. This flange can support the seat retainer.

4. Can a butterfly valve be used for flow control?

Yes. Butterfly valves, like needle valves, have good control capacities.

5. What is the difference between the ball valve and butterfly valve?

The butterfly valve with the same specification as the ball valve is usually cheaper in price and easier to install. Easier maintenance may go in recognition to ball valves as butterfly valves have a disc that can block some impurities that got stuck. Furthermore, ball valves are used in most high-pressure applications because they are more suitable for high differential pressures as compared to butterfly valves.

Butterfly valves are simpler in design, having lesser moving parts. Ball valves material and torque use is only low for narrower pipe diameters. For butterfly valves, it may start from DN 50mm and above.

6. How to Avoid Problems with Butterfly Valves?

Most of the major problems with butterfly valves are a result of poor installation and not the device itself. Therefore, it should be noted that in order to reduce maintenance work, butterfly valves should be properly installed during the commissioning stage.

- One of the things that should be inspected during installation is the elastomer seal. It tends to move towards the face of the valve and gets compressed while you install it. So its effects, it will easily wear away and will not effectively perform its duty of sealing the valve during operation. Hence, care must be put when installing the valve so it should not conceal the seal material.

- Another scenario is when the disc extends outside the surface of the body and close in with the valve. Therefore, it should be inspected that the disc can turn freely while it enters the flanges.

Conclusion

So there. We have finally reached the end of this guide. We hope that it has given you a better understanding of a butterfly valve; its operation, maintenance and installation. Most importantly, we hope that it gave you an idea on how you can choose and buy butterfly valves from manufacturers/suppliers.

Huamei is a high-performance butterfly valve manufacturer and supplier for many years. We are dedicated to helping you deliver the best performance butterfly valves in the market. Please do contact us for more details if you have any queries.