How to Measure Butterfly Valves

Gate Valve Vs. Butterfly Valve

September 10, 2019

What is a Double Offset Butterfly Valve

September 12, 2019How to size and select high-performance butterfly valves according to physical criteria, pressure rating, and international standards.

High-performance butterfly valves are used not only used in tight shut-off in piping systems but also for flow control and throttling services. Butterfly valve manufacturers see to it that these valves are manufactured with high levels of accuracy, have passed multiple QC criteria and carry the distinctive features that make them suitable for high pressure and temperature requirements.

Hence, on your part as a purchaser, the correct sizing, measurement, and selection of high-performance butterfly valve can provide you with an undoubtedly reliable and accurate fluid delivery. Choosing an accurate size and measurement of a butterfly valve significantly increases plant efficiency. This follows an uptrend in overall profitability for your business and a significant return on investment on your part.

In this article, we will explain how to accurately measure and size a butterfly valve for your application and piping system requirements.

The Anatomy of a Butterfly Valve

First, let’s have a recap on the basic parts and anatomy of a butterfly valve before we jump into the ways you can measure it.

A butterfly valve is a quarter-turn valve that initiates throttling and flow control of fluids. It has a thin metal disc that rotates about the stem. The opening and closing mechanism allow and restrict the flow of a medium between an upstream and downstream pipe.

Ideal Measurements Based on International Standards

Butterfly valves are used in many applications that’s why organizations have made a number of international standards for the manufacture of these valves. Butterfly valve standards ensure that there would be uniformity in designs and compatibility with other components such as the flange.

It is therefore essential that engineers and valve designers review these standards. To name some of the organizations providing these standards, here are some listed below:

- International Organization for Standardization

- European Committee for Standardization

- ANSI Valve Standards (United States)

- BSI Valve Standards (United Kingdom)

- CSA Valve Standards (Canada)

- DIN Valve Standards (Germany)

- EEMUA Valve Standards (United Kingdom)

- JSA Valve Standards (Japan)

AWWA C504 for Rubber-Seated Butterfly Valves

These are butterfly valves specified by the American Water Works Association. They are used to process potable water. This standard is intended for sizing AWWA rubber seated butterfly valves. Therefore, all measurements and testing procedures should conform with the specifications in this standard.

API 609 for Lug and Wafer Butterfly Valves

Manufacturers meet this standard for uniformity in design, materials and face-to-face dimensions. It also covers pressure-temperature ratings and inspection of the valves for different materials (gray iron, ductile iron, bronze, steel, nickel).

According to this, the range of sizes can be:

- 2” to 12” at 200 psi gauge pressure WOG service.

- 14″ to 30″, rated pressure can be 150 psi gauge at WOG service.

Standard tests for bidirectional applications and bubble tight shutoff are also covered in this standard. For lug-style end connections, the valves are made suitable for ANSI 125/150 lb, JIS, DIN or B.S. Flanges.

MSS SP-67 for General Butterfly Valves

MSS SP-67 is a butterfly valve standard for listing proper dimensions, testing, marking and design. It covers the standard sizes:

- NPS (nominal pipe size) 1½ to NPS 72.

UL 1091 for Safety Butterfly Valves for Fire Protection Services

The UL 1091 standard specifically covers the requirements for butterfly valves utilized in the fire-protection services. If you are designing valves for this type of service, you should look into the proper dimension, design, installation and testing requirements in this standard.

How to Determine Butterfly Valve Dimensions

Butterfly valve sizes may generally range from 2 inches to 60 inches, but there are those available up to 96 inches, depending on the manufacturer.

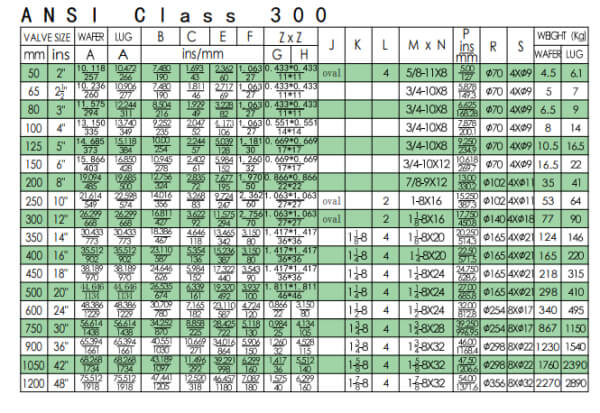

As mentioned earlier, standards have set dimensions for face to face lengths and weight for the butterfly valves. Most of the valve manufacturers clearly specify these in their catalogs. You can typically find ASME pressure classes (Class 150, 300 and 600) available from different manufacturers. This can allow up to 1,500 psi maximum pressure.

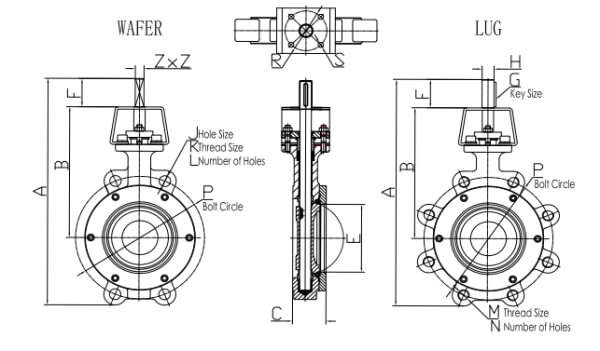

Generally, when you see a “valve size” measured in inches or mm, it refers to the diameter of the valve that is equal to the nominal pipe diameter that connects to the valve. Here is an excerpt from Huamei’s Butterfly Valve catalog which shows how you can measure butterfly valve.

- Length A – Length of butterfly valve body + stem endpoint.

- Length B – Length from centerline x-axis to valve end

- Length C – thickness of the valve body

- Length F – length of the key

- Length H – diameter of stem

- Length J – Hole size

- K – thread size

- L – number of holes

- P – diameter of circle from center of lug hole

If you are planning to purchase a butterfly valve, you should ask the manufacturer for a catalog that specifies the range of sizes you can choose from. Manufacturers should also provide a complete size and dimension table such as the one below.

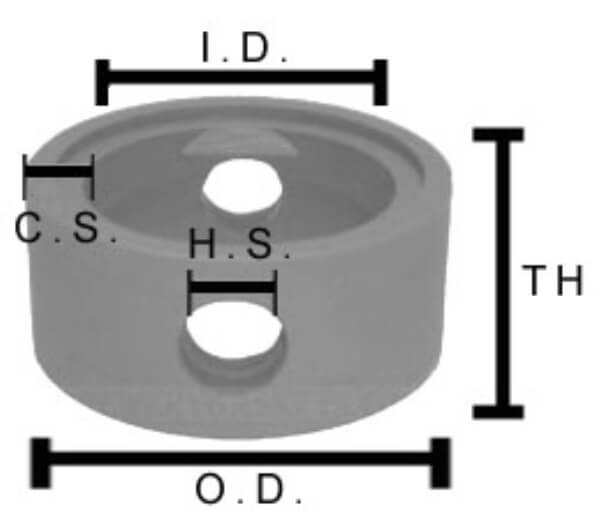

Measuring Valve Seat Size

There are instances where you need to fix and replace a butterfly valve seat and this calls for you to purchase the right seat size from a supplier. In order for you to measure the size of the valve seat, you can follow this photo. Remember to use a caliper in measuring the valve seat dimensions so you can be precise with your measurements.

Where:

- HS – Diameter of Side Bore, mm

- TH – Height of Seat, mm

- CS – Thickness of Seat, mm

- ID – Internal Diameter of seat, mm

- OD – Outer Diameter of seat, mm

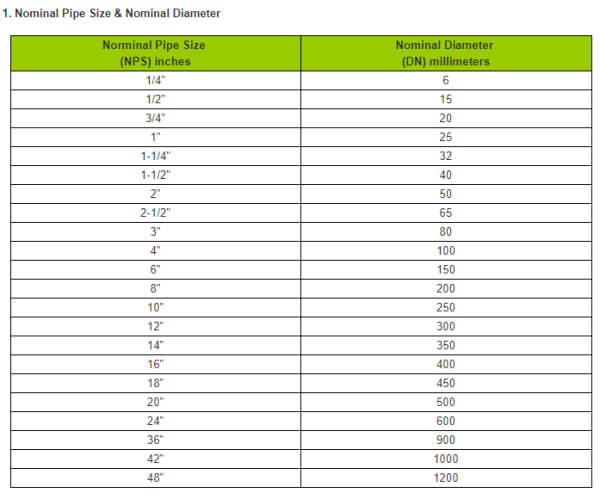

What is the Difference Between DN/PN and NPS/Class?

As you may have observed in most butterfly valve manufacturers’ specifications, there are DIN ISO, PN10, PN16, PN25, PN40 and other pressure-temperature rating standards.

These specifications may either refer to the english system or metric system.

The english or imperial system uses british units such as PSI for pressure, and NPS or nominal pipe size is used to describe the pipe diameter.

For metric specifications, kPa or bar is used to denote the pressure while DN is for the nominal diameter.

So when you see a “PN” in specs, it means that the valve is manufactured following the ASME pressure class. The PN classes corresponds with the “DIN” rating standard for pressure and temperature for flanges in metric system.

For example, the PN10, PN16, PN25 and PN40 are pressure classes in bars of pressure, and metric flange sizes (such as bolt circle diameter, hole size, bolt size) are manufactured following standards of ISO 7005-1 or DIN 2501 that use the metric system.

Generally, flanges that have ANSI or AWWA specs will not be compatible with flanges produced in the metric system.

The following table indicates the NPS sizes corresponding with its DN sizes. You can use this table as a reference when selecting butterfly valve sizes.

Nominal Pipe Size and Nominal Diameter

Butterfly Valve Sizing

Butterfly valve sizing is a way of selecting the appropriate valve size for your application. Sizing a butterfly valve used for flow control is a long and tedious process. But today, there are several specialized programs that can readily size the butterfly valve needed for a specific volume flow rate of fluid.

There are a lot of variables to determine in order to come up with the right valve size to sustain your system requirements.

Determining the Pressure Drop

In order to get the volume coefficient, you should get to the pressure drop calculation first. The simplest procedure is to determine the pressure at the upstream of the valve (P1) and the pressure downstream (P2). Subtract P2 from P1.

ΔP = P1 – P2

Note that energy costs increases with excessive pressure drop so be mindful to minimize pressure drops between the upstream and downstream portion of the valve when you design a piping system.

Measuring the Coefficient of Volume (CV)

Determine the flow coefficient or the Cv. Cv measures the capacity of the valve body and trim and is expressed in GPM or gallons per minute. This is the volume of water that will pass through at 60°F (15.5°C) at a 1 PSI pressure drop.

To put it simply, imagine a butterfly valve at its full open position. If this valve has a calculated Cv of 15 GPM/PSI, it means that 15 gallons can pass through per minute with a pressure drop of 1 PSI.

The simple formula for the CV is:

Cv = QS/ΔP

Where:

Cv = valve flow coefficient

Q = volume flow rate in GPM

S = specific gravity of fluid @ 60°F

ΔP= pressure drop

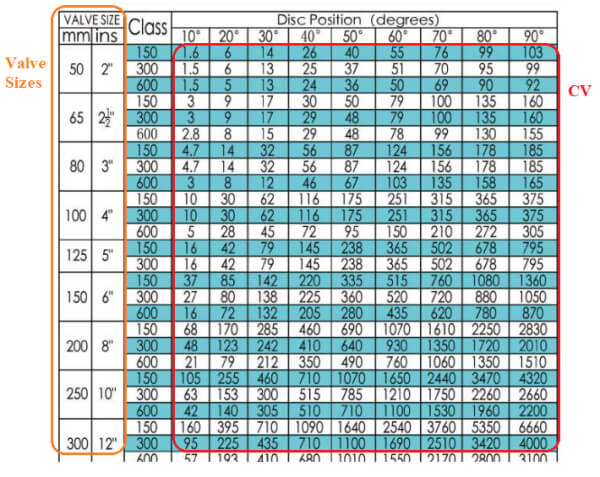

In actual practice, once you determine the design flow rate of your system and the pressure drop, then you can calculate the Cv. The Cv should be calculated correctly to accurately size and select a butterfly valve. Typically, manufacturers provide a Cv table to guide engineers on which valve size to choose such as the one below.

Edited Huamei Machinery file for Valve Flow Coefficients

This table is an excerpt from Huamei Machinery’s Valve Flow Coefficient chart for selecting butterfly valves. As you can see, the chart has a recorded Cv factor for Huamei’s valve classes and sizes for every 10 degree increments between open and close position.

Conclusion

There are multiple ways to measure a butterfly valve. It can be through physically measuring its dimensions or through sizing its pressure rating. If you want to purchase butterfly valves, you must first know which size to choose and what pressure class you need.

We hope that this article has helped you know how to correctly size and select butterfly valves. Still confused? You may contact us through our website and ask for more queries on how to measure and select butterfly valves.

Our company manufactures High-Performance Butterfly Valves available in a variety of material and end-connection types. We also cater OEM/ODM needs.